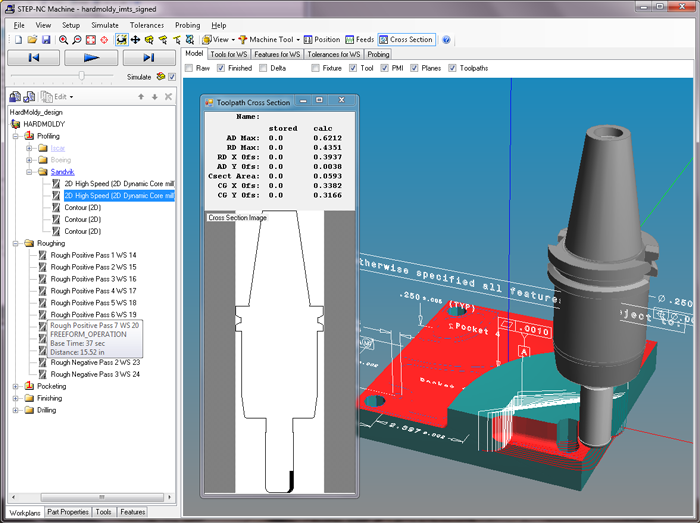

As you use STEP-NC Machine

to simulate material removal, you can see

the cross section of the material being cut as well as some key

parameters calculated from that cross section. The parameters might

also be stored in the file, but the calculated ones are only available

when simulating.

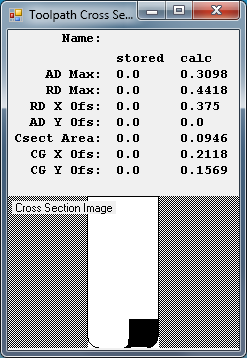

As you use STEP-NC Machine

to simulate material removal, you can see

the cross section of the material being cut as well as some key

parameters calculated from that cross section. The parameters might

also be stored in the file, but the calculated ones are only available

when simulating.

Bring up the Tool Cross Section window by clicking

the  Cross Section

button or selecting the

View | Toolpath Cross Section menu entry. The window shows the

tool coordinates, axis direction, feedrate and spindle speed of the

tool at the current toolpath location.

The cross section parameters are calculated from the material removal

simulation, but certain files may also have the parameters stored with

the toolpath. These parameters describe a 2D profile in the plane

normal to the feed direction.

Cross Section

button or selecting the

View | Toolpath Cross Section menu entry. The window shows the

tool coordinates, axis direction, feedrate and spindle speed of the

tool at the current toolpath location.

The cross section parameters are calculated from the material removal

simulation, but certain files may also have the parameters stored with

the toolpath. These parameters describe a 2D profile in the plane

normal to the feed direction.

AD Max is the maximum axial depth and RD Max is the maximum radial depth of the tool contact cross section. The axial depth is measured parallel to the tool axis while the radial depth is perpendicular to both tool axis and feed direction.

RD X Ofs is the radial offset and AD Y Ofs is the axial offset of the origin (lower left corner) of tool contact cross section. These offsets are measured from the tool tip.

Csect Area is the total cross section area of the tool engagement. CG X Ofs and CG Y Ofs are the radial and axial offset of the center of gravity of this cross section area. They are also measured from the tool tip.