STEP Tools Corporate Timeline

-

STEP Tools, Inc. founded in Troy, New York, a city with a two hundred year history of manufacturing and industry.

-

First Geometry Exchange

STEP Tools® software used in the very first exchange of STEP CAD geometry, an automotive connecting rod exchanged between Ford and Allied Signal and then machined.

-

STEP Published

STEP (STandard for Exchange of Product model data) becomes a full ISO standard

-

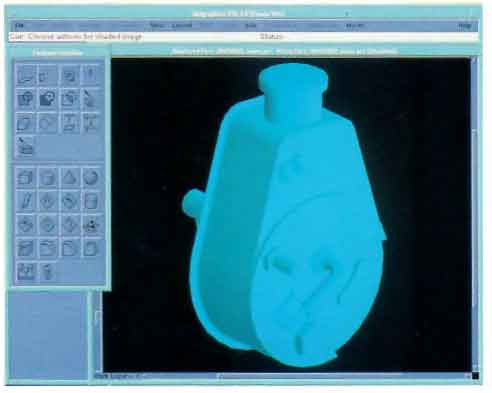

STEP CAD Deployment Begins

The first wave of STEP CAD implementation begins with pilot projects like the water pump exchange between Ford and Allied Signal, and "AeroSTEP" with Boeing and its engine suppliers. STEP Tools® software, consulting, and training expertise used by projects and CAD vendors during this process.

-

First Web Service Launched

Free online STEP Tools® Data Translation Service Launched for public usage.

-

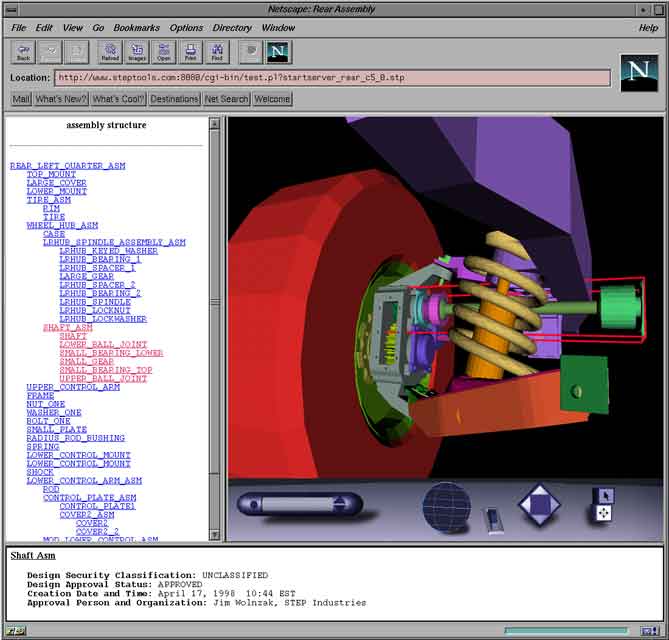

STEP Geometry on the Web

STEP Tools® sofware demonstrated visualization of STEP assemblies within a web browser using a variety of 3D display technologies.

-

STEP Tools, Inc. awarded $2M under the Advanced Technology Program by the National Institute of Standards and Technology, for the Model Driven Intelligent Control of Manufacturing project, which ultimately created STEP-NC AP238, a core part of the digital thread.

-

STEP Tools, Inc. forms Industrial Review Board for STEP-NC Super Model project.

-

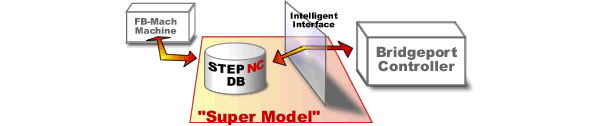

The First US Demonstration of STEP-NC AP238, at the Watervliet Arsenal. This showed the first glimpse of the digital thread, with STEP design data attached to an AP238 machining plan for a 2.5D part, then machined from that integrated description by a Bridgeport with a STEP-NC control.

-

STEP Tools, Inc. opens North American Center for STEP-NC Technology to serve as a focal point for next-generation manufacturing

-

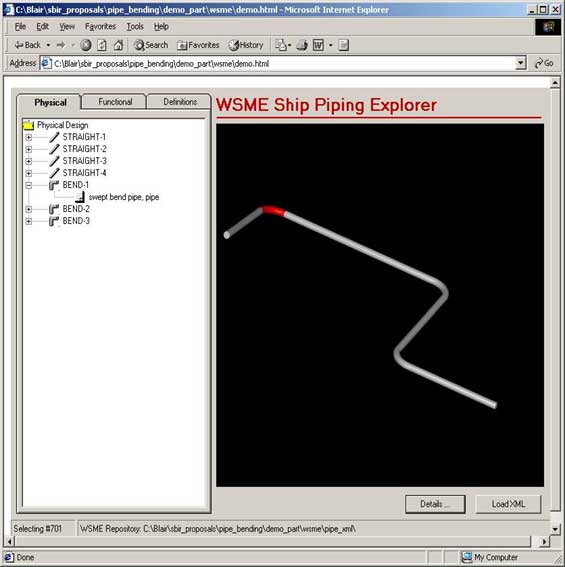

New Manufacturing Areas

STEP Tools, Inc. begins expanding STEP-NC to new manufacturing areas, like pipe bending and cutting

-

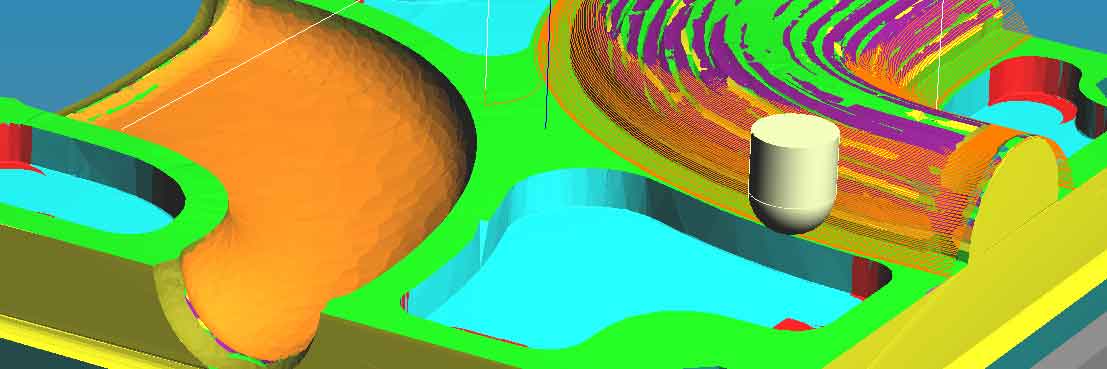

STEP Tools, Inc. demonstrates AP238 for multi-axis machining at JPL followed by 5-axis surfacing at NIST.

-

AP238 Testing Forum begins showing multiple CAMs producing AP238, and 5-axis parts machined from a single AP238 description on multiple machines with completely different geometries.

-

STEP Tools, Inc. and General Dynamics Electric Boat demonstrate a prototype digital thread connecting shipyard design to plate cutting and laser marking. This NSRP project identified extensions to AP238 for steel processing.

-

AP238 Standard Published

ISO publishes AP238 as the ISO 10303-238 standard.

-

STEP Tools, Inc. and others demonstrate digital thread concepts showing models of the product, product tolerances, process, fixtures and cutting tools used for on-machine feed-speed and tool life optimization, with closed loop machining using measurement devices such as probes and Faro arms.

-

STEP Tools, Inc. begins National Simulation Service DARPA SBIR Project which produced the material removal simulator used to create our digital twins on the digital thread.

-

STEP Tools, Inc. works with Boeing, Okuma, ISCAR, and Sandvik Coromant to show a 15-30% improvement in machining time from collaboration on a digital thread using STEP-NC.

-

First demonstration of STEP Tools® Digital Twin Server connecting the Digital Thread across machining and inspection.